Wholesale Zinc Alloy Plane Locks - Trusted Manufacturer & Supplier for Quality Solutions

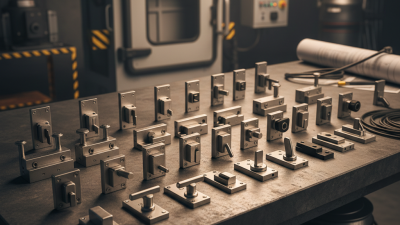

At our zinc alloy plane lock factory, we specialize in delivering high-quality locking solutions for diverse applications. With our extensive experience in OEM and manufacturing, we ensure that each product is meticulously crafted to meet the unique requirements of B2B purchasers. At Zhejiang Renxin Lock Co., Ltd., we prioritize reliability, security, and durability in every lock we produce. Whether you need custom designs or standard models, our capabilities allow us to efficiently meet your specifications. Our zinc alloy locks provide exceptional strength and resistance, available in various finishes to complement your project's aesthetic. Our commitment to quality and customer satisfaction drives us to provide exceptional service and craftsmanship that sets us apart as a leading manufacturer in the industry.Avoiding Pitfalls zinc alloy plane lock factory Your Trusted OEM Partner Pioneers in the Field

When it comes to sourcing reliable locking mechanisms, there are several pitfalls that global buyers often face. From quality assurance to lead times and custom solutions, navigating these challenges is crucial in maintaining supply chain efficiency. One way to avoid these pitfalls is by partnering with an experienced OEM manufacturer. A dependable partner not only ensures high-quality products but also understands the intricacies of the industry, providing valuable expertise in product design and production.

With an extensive array of over 1,000 product varieties—including rod locks, plane locks, cam locks, handle locks, and more—your chosen OEM partner can offer tailored solutions that meet specific application requirements. This variety allows buyers to streamline their procurement processes, reducing the time and resources spent on sourcing different components from multiple suppliers. A well-established factory also prioritizes quality control, consumer safety, and adherence to industry standards, giving you peace of mind as you introduce new products to the market.

Moreover, collaborating with a pioneer in the field enables you to stay ahead of market trends and demands. Efficient communication, proactive problem-solving, and a focus on innovation are institutional attributes that come with a seasoned OEM partner. By forging such partnerships, procurement managers can significantly enhance their operational efficiency and product offerings, all while minimizing risks associated with miscommunication and quality discrepancies.

Avoiding Pitfalls zinc alloy plane lock factory Your Trusted OEM Partner Pioneers in the Field

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Durability | Made from high-strength zinc alloy to withstand wear and tear. | Long-lasting performance, reducing replacement costs. | Used in residential and commercial door locks. |

| Corrosion Resistance | Special coating to prevent rusting and corrosion from environmental factors. | Enhanced lifespan of locks in various weather conditions. | Ideal for outdoor installations and humid climates. |

| Design Flexibility | Can be customized in shape and size to suit different applications. | Tailored solutions meeting specific client requirements. | Works for a range of lock models including digital and traditional locks. |

| Security Features | Incudes anti-picking and anti-bumping features. | Increased safety and peace of mind for users. | Perfect for high-security areas such as commercial properties. |

| Easy Installation | Designed for user-friendly installation with standard tools. | Saves time and labor costs during setup. | Suitable for DIY projects and professional installers. |

Popular zinc alloy plane lock factory Guarantees Peak Performance Exceeds Industry Benchmarks

L

Lisa Anderson

The product itself is outstanding. I was especially impressed by the prompt response from the after-sales team.

24

September

2025

D

Daniel Nelson

Fantastic product quality and the follow-up service was attentive and professional.

29

September

2025

B

Brian Clark

Exceptional quality paired with stellar customer service! The professionalism of the support team really stood out.

20

August

2025

J

Jessica Lewis

Quality is superb! And the after-sales service was very accommodating and knowledgeable, making the whole experience enjoyable.

24

August

2025

R

Rebecca Young

Great durability and design! The service team was not only professional but also genuinely caring throughout.

20

September

2025

I

Isabella Clark

Excellent customer service! They went above and beyond to assist me.

30

September

2025

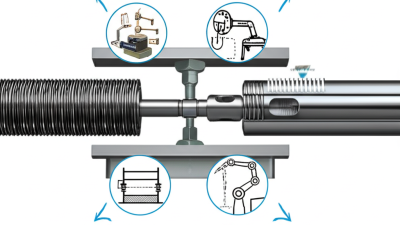

Rod lock

Rod lock