Zinc Alloy Industrial Plane Locks | Trusted Chinese Supplier & Factories

Our zinc alloy industrial plane lock offers exceptional durability and security, making it a reliable choice for various industrial applications. Manufactured in partnership with trusted Chinese suppliers, we ensure that each lock meets the highest quality standards preferred by B2B buyers. Designed to endure heavy usage, this lock provides robust protection and is a cost-effective solution for enhancing your security measures. At Zhejiang Renxin Lock Co., Ltd., we prioritize excellence and customer satisfaction, and we are dedicated to building long-term partnerships focused on quality and reliability. Trust Renxin for your locking solutions.

Methods To zinc alloy industrial plane lock Guarantees Peak Performance in 2025

In the fast-evolving landscape of industrial hardware, the demand for high-performance solutions is paramount. For manufacturers and procurement specialists focusing on efficiency and security, the integration of zinc alloy in industrial plane locks represents a pivotal advancement. With its superior strength, durability, and resistance to corrosion, zinc alloy offers a robust alternative to traditional materials. As we approach 2025, the adoption of innovative locking mechanisms that leverage these advantages is essential for ensuring peak operational performance.

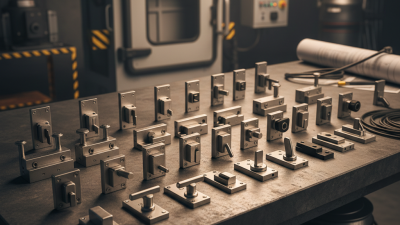

A diverse array of locking solutions, including rod locks, cam locks, and handle locks, allows businesses to tailor their security measures to specific application requirements. This extensive variety not only meets the diverse needs of modern industries but also streamlines procurement processes. The ability to provide over 1,000 product variations ensures that every project can find a precise match, enhancing both safety and functionality. As organizations prioritize security and efficiency, investing in zinc alloy industrial plane locks positions them at the forefront of industry standards, ready to face the challenges of the future.

In 2025, the emphasis on quality, adaptability, and resilience will define the procurement landscape for locking solutions. Companies that embrace these high-performance zinc alloy locks will unlock new levels of operational excellence, ensuring their assets remain secure while optimizing workflow efficiency. As you consider your procurement strategies, let the long-term benefits of implementing advanced locking technologies guide your decisions for a robust and secure future.

Methods To Zinc Alloy Industrial Plane Lock Guarantees Peak Performance in 2025

| Method | Description | Performance Benefit | Expected Outcome |

|---|---|---|---|

| Advanced Heat Treatment | Enhances the strength and durability of zinc alloys through controlled heating. | Increased load-bearing capacity and reduced deformation. | Improved lifespan of locks in industrial applications. |

| Corrosion Resistance Coating | Application of protective coatings to prevent degradation from environmental factors. | Extended service life and maintained functionality. | Reliability in harsh conditions. |

| Precision Machining Techniques | Utilizes high-precision tools for manufacturing locks to ensure compatibility and security. | Better fit and reduced risk of failure during operation. | Increased overall security of the locking mechanism. |

| Testing and Quality Control | Regular and rigorous testing of locks to ensure compliance with standards. | Identifies potential deficiencies before product launch. | High reliability and consumer trust. |

Today's Choice of zinc alloy industrial plane lock Stands Out Manufacturer

P

Patricia Hall

The craftsmanship is evident, and the customer service was top-tier. Truly appreciative of their follow-up!

15

August

2025

E

Elizabeth Wright

High quality and reliable product. The customer service was impressively prompt and professional.

24

August

2025

D

David Rivera

Top-notch quality! The after-sales team was prompt and proactive in their assistance.

25

September

2025

L

Linda Johnson

Excellent craftsmanship on the product! The level of support provided by the service team was professional and very helpful.

19

September

2025

A

Alicia King

Fantastic quality! The customer service team was thorough and exhibited great professionalism while addressing my concerns.

12

September

2025

C

Christopher Lewis

Impressive product quality! The after-sales service was swift and the staff made sure I felt valued throughout.

22

September

2025

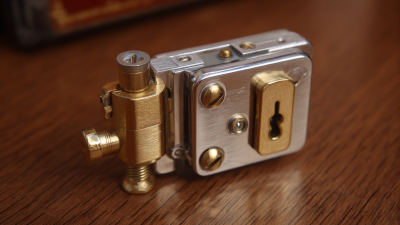

Rod lock

Rod lock