Introduction to the Rod Connecting Lock

In the complex and high-stakes environment of industrial electrical systems, ensuring absolute operational safety requires more than procedural rules—it demands physically integrated, fail-safe mechanisms. The Rod Connecting Lock represents a critical evolution in safety engineering, serving as the mechanical backbone of multi-panel interlocking systems.

The system operates through a robust network of precisely engineered steel rods, levers, and cam mechanisms that physically link the operating handles of circuit breakers or disconnect switches to the access doors of multiple interconnected panels. This mechanical linkage enforces a non-negotiable operational sequence, making safety inherent to the equipment’s function. For example, in a main-tie-main distribution board, the rods ensure the tie-breaker cannot be closed unless both main breakers are open, preventing a catastrophic parallel connection of power sources. Simultaneously, the rods block access to any panel door until all associated switches in the sequence are verified to be in the safe “OFF” or “isolated” position.

By physically preventing improper sequencing—both during shutdown for maintenance and during system re-energization—the Panel Rod Connecting Lock mitigates the severe risks of arc flash incidents, electrocution, and equipment damage. Its purely mechanical design guarantees reliability without dependency on software, sensors, or electrical power, ensuring functionality even during system failure.

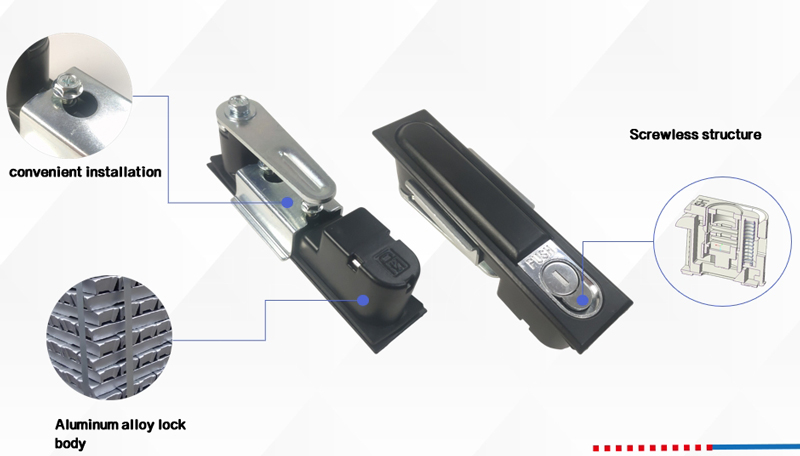

As a cornerstone of modern electrical safety standards, such as Renxin lock MS828,MS741-1and MS836 and so on. this interlocking system embodies the principle that the highest level of safety is engineered directly into the equipment’s operation. It provides an immutable physical barrier against human error, ensuring that the safety of personnel and the integrity of critical infrastructure are permanently and mechanically interlocked.

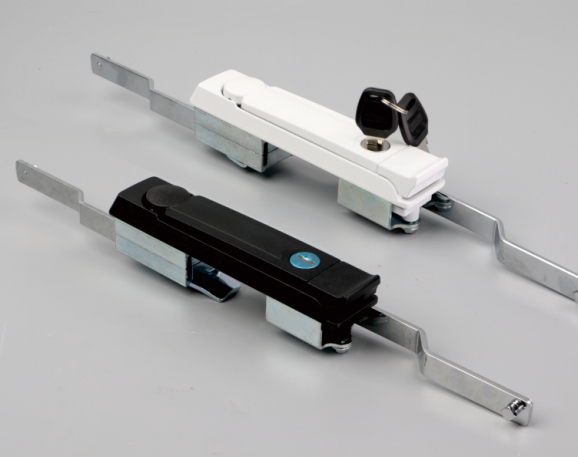

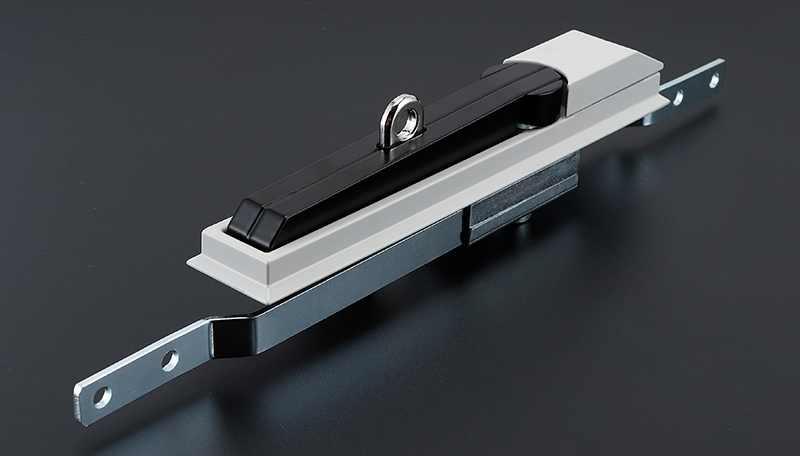

Rod lock

Rod lock