Custom ODM Solutions for Drawing Handles by Leading Manufacturers and Factories

As a leading manufacturer of high-quality drawing handles, we understand the importance of OEM solutions for manufacturers seeking reliability and durability. Our handles are produced in Zhejiang, where we maintain rigorous quality control throughout the entire process. We cater to factories that demand precision and performance, ensuring our products comply with various industry standards. Choosing our drawing handles not only guarantees superior craftsmanship but also a dependable partnership. We focus on your specific needs, collaborating closely to provide customized solutions that align with your production requirements. Our experienced team recognizes the market's nuances, enabling us to offer competitive pricing and timely delivery. Whether you're expanding your production capacity or requiring distinctive designs, we are here to support you. Our dedication to quality and customer satisfaction has made us a trusted alternative among suppliers in the industry. Let's work together to enhance your product offerings!Step-by-Step Guide Drawing Handle Application Factory

In today’s evolving manufacturing landscape, understanding the intricacies of handle application is crucial for global procurement professionals seeking to enhance their product offerings. This step-by-step guide is designed to help you navigate the process of drawing handle applications, ensuring that you find the right solutions tailored to your specific needs. With an extensive selection of over 1,000 product varieties, it’s possible to address even the most unique application requirements efficiently and effectively.

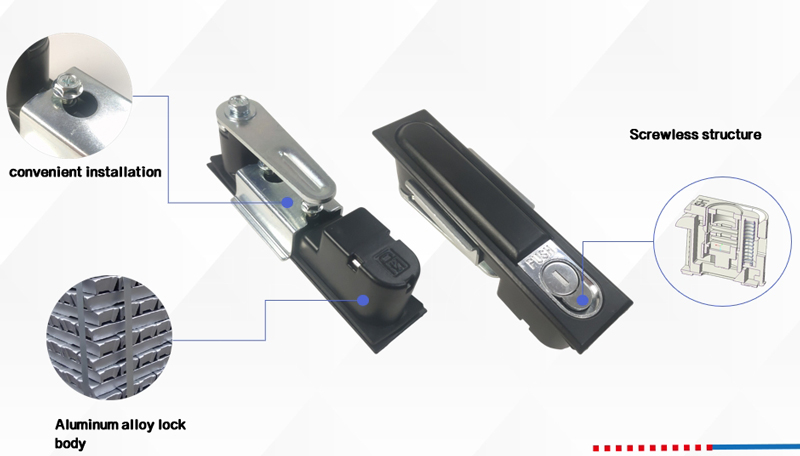

Starting with the fundamentals, it's essential to identify the specific requirements for your handle application. Consider factors such as load capacity, environmental conditions, and aesthetic preferences. The next step involves exploring various locking mechanisms that can complement your handles, including rod locks, cam locks, and hinge systems. These components not only enhance functionality but also contribute to the overall security and design of your products.

As you advance through the selection process, collaboration with manufacturers who possess deep expertise in the industry is vital. A knowledgeable partner will provide insights into material choices, design feasibility, and manufacturing capabilities, empowering you to make informed decisions that align with your business objectives. By following this structured approach, procurement professionals can streamline their sourcing efforts, ultimately leading to the successful integration of innovative handle applications in their offerings.

Step-by-Step Guide Drawing Handle Application Factory

| Step Number | Process Description | Tools/Materials Needed | Estimated Time |

|---|---|---|---|

| 1 | Research different handle designs and functionalities. | Internet, Design Books | 2 hours |

| 2 | Create initial sketches of the handle design. | Pencil, Paper, Sketchbook | 3 hours |

| 3 | Select materials for the handle fabrication. | Material Samples, Data Sheets | 1 hour |

| 4 | Develop 3D models of the handle using CAD software. | CAD Software, Computer | 5 hours |

| 5 | Create prototypes of the handle. | 3D Printer, Materials | 4 hours |

| 6 | Test the prototypes for functionality and comfort. | Testing Tools, Feedback Forms | 2 hours |

| 7 | Finalize design based on test feedback. | Design Software, Documentation | 2 hours |

Why Trust Drawing Handle Is The Best Application

C

Christopher Lee

High-quality materials and great performance. The after-sales service staff handled my inquiries with expertise.

03

September

2025

S

Sarah Davis

Impressive craftsmanship and excellent service. The representatives are well-trained and courteous.

18

September

2025

C

Charles Adams

Quality product that delivers! The after-sales team is incredibly well-trained and responsive.

27

September

2025

N

Nancy Harris

This purchase met all my quality expectations. Their customer service truly stands out!

07

October

2025

J

Jack Baker

Great quality and amazing support! The after-sales staff showed genuine concern for my satisfaction.

30

September

2025

L

Linda Green

Delighted with my product! The service staff were well-trained and resolved my queries efficiently.

02

September

2025

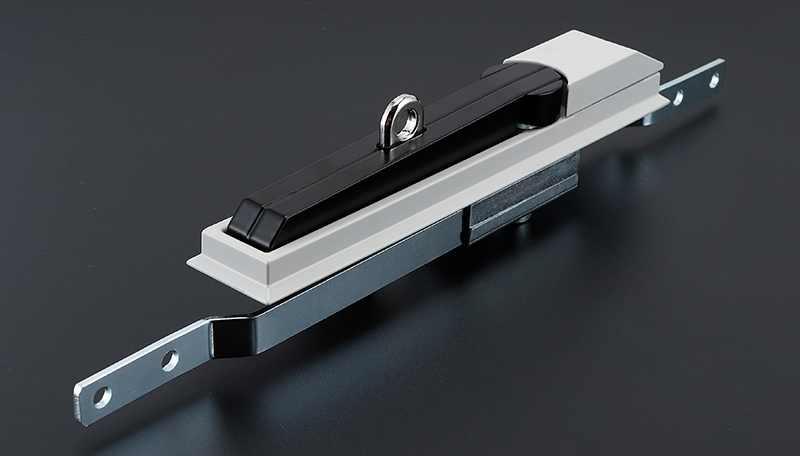

Rod lock

Rod lock